LV and HV cables are essential components in electrical power systems that help in transmitting electricity from one location to another.

They are used to transmit power from generating stations to transformers, and then to distribution networks, which eventually supply power to homes, businesses, and industries.

In this article, we will discuss the different types of LV and HV cables, their properties, and aptheir plications.

Table of Contents

What are LV and HV cables?

LV cables are low voltage cables that are designed to transmit electrical power at voltage levels up to 1000 V.

They are typically used for short-distance power transmission and distribution, such as within buildings and homes.

In contrast, HV cables are high and medium-voltage cables that are designed to transmit electrical power at voltage levels above 1000 V.

They are typically used for long-distance power transmission and distribution, such as between power plants, substations, and transmission towers.

Types of LV cables

There are several types of LV cables, each designed for a specific application. Some of the common types of LV cables include:

PVC cables

Polyvinyl chloride (PVC) cables are the most commonly used type of LV cables. They are made of PVC insulation and sheathing material and can be used for a wide range of applications.

PVC cables are generally flexible and easy to install, making them ideal for use in buildings, homes, and small industries.

XLPE cables

Cross-linked polyethylene (XLPE) cables are another type of LV cables that are commonly used for power transmission and distribution.

They have a higher current carrying capacity than PVC cables and are more suitable for applications that require high power transmission.

XLPE cables are also more resistant to heat, moisture, and chemicals, making them ideal for outdoor applications.

Rubber cables

Rubber cables are a type of LV cable that is used in applications that require high flexibility and durability.

They are made of natural or synthetic rubber insulation and sheathing material and are commonly used in industries, construction sites, and mining applications.

Control cables

Control cables are a type of LV cable that is used for transmitting control signals and data between different electrical components.

They are typically used in industrial automation and process control systems and are made of PVC, XLPE, or rubber insulation and sheathing material.

Types of HV cables

Similar to LV cables, there are several types of HV cables that are designed for different applications. Some of the common types of HV cables include:

XLPE cables

Cross-linked polyethylene (XLPE) cables are also commonly used for HV applications. They have a higher insulation capacity than PVC cables and are more suitable for applications that require high-power transmission over long distances.

Oil-filled cables

Oil-filled cables are a type of HV cable that uses oil as an insulation material. They are commonly used for long-distance power transmission, such as between power plants and substations.

Oil-filled cables are more expensive than XLPE cables but are more suitable for applications that require high-voltage transmission over very long distances.

Gas-insulated cables

Gas-insulated cables are a type of HV cable that uses gas as an insulation material. They are commonly used for underground power transmission and distribution and are more expensive than XLPE and oil-filled cables.

Gas-insulated cables are more suitable for applications that require high-voltage transmission in densely populated areas, where space is limited.

Comparison Table

| Type of Cable | Voltage Range | Insulation Material | Sheathing Material | Typical Applications |

|---|---|---|---|---|

| PVC cable | Up to 1000 V | PVC | PVC, LSZH | Buildings, homes, low voltage systems |

| Rubber cable | Up to 1000 V | Rubber | Rubber | Industries, construction sites, mining |

| Control cable | Up to 1000 V | PVC, XLPE, rubber | PVC, LSZH | Industrial automation, process control systems |

| XLPE cable | Above 1000 V | XLPE | PE, PVC, LSZH | Power transmission and distribution |

| Oil-filled cable | Above 1000 V | Oil | Lead, PE | Long-distance power transmission |

| Gas-insulated cable | Above 1000 V | Gas | Lead, PE | Underground power transmission and distribution |

why hv cables have a screen of a semiconductor?

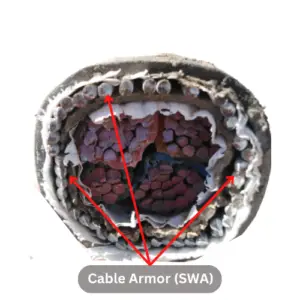

HV cables have a screen of a semiconductor because it helps to reduce the electrical stress on the insulation of the cable.

The screen is typically made of a layer of extruded or laminated semiconductor material, and it is located between the insulation and the metallic shielding.

When high voltage electricity is transmitted through the cable, it generates an electric field around the cable, which can cause the electrical stress on the insulation to increase. This can lead to premature breakdown of the insulation and cause the cable to fail.

The semiconductor screen helps to reduce the electrical stress by distributing the electric field more evenly over the surface of the insulation, thereby minimizing the concentration of electric field at any one point.

In addition to reducing the electrical stress, the semiconductor screen also helps to prevent the formation of air pockets between the insulation and the metallic shielding, which can cause partial discharges and lead to insulation breakdown.

The screen acts as a smooth interface between the insulation and the metallic shielding, reducing the likelihood of partial discharges.

Overall, the semiconductor screen is an important component in HV cables, as it helps to improve the reliability and performance of the cable by reducing the electrical stress and preventing partial discharges.

When HV Semiconductors May Need to be Removed from Cables?

According to IEEE Standard 48-2019, “Guide for the Design and Installation of Cable Systems in Substations,” the semiconducting layer of a high-voltage cable should be left intact when using a cold shrink termination.

The standard specifies that the termination is designed to function properly with the semiconducting layer in place. Therefore, there is no need to remove the semiconducting layer when using a cold shrink termination.

Similarly, IEC 60287-1-1:2014, “Electric Cables – Calculation of the Current Rating – Part 1-1: Current Rating Equations (100% Load Factor) and Calculation of Losses – General,” recommends that the semiconducting layer should not be removed from the cable when using a cold shrink termination.

According to the standard, the semiconducting layer is an integral part of the cable structure, and it should remain in place during installation of the termination.

However, when using a heat shrink termination, the semiconducting layer may need to be removed to ensure proper adhesion of the termination. In this case, the manufacturer’s instructions should be followed carefully to ensure that the semiconducting layer is removed correctly, and the termination is installed properly.

In summary, whether or not to remove the semiconducting layer during cable termination depends on the type of termination being used.

For cold shrink terminations, the semiconducting layer should be left in place, while for heat shrink terminations, it may need to be removed.

It is important to follow the relevant standards and the manufacturer’s instructions to ensure that the termination is installed safely and correctly.

References:

- IEEE Standard 48-2019, “Guide for the Design and Installation of Cable Systems in Substations”

- IEC 60287-1-1:2014, “Electric Cables – Calculation of the Current Rating – Part 1-1: Current Rating Equations (100% Load Factor) and Calculation of Losses – General”

Conclusion

LV and HV cables are essential components in electrical power systems that help in transmitting electrical power from one location to another.

The type of cable used depends on the voltage range, insulation and sheathing material, and the specific application.

PVC, XLPE, rubber, and control cables are commonly used for LV applications, while XLPE, oil-filled, and gas-insulated cables are used for HV applications.

Understanding the different types of LV and HV cables is critical in selecting the right cable for a specific application.

Don’t Leave Empty-Handed!

Install my Free Android App on Google Play:

Electrical Cables Most Common Tables “Cables Tables”

And, my Electrical Calculations App “Fast Electrical Calculator”

Discover more great content by subscribing to My channel

Looking to stay ahead of the game in the world of electrical engineering? Subscribe to my YouTube channel and gain access to exclusive content you won’t find anywhere else!

The staff I recommend

(Amazon Affiliate Links to products I believe are high quality):

- Economy 120 Volt/60Hz AC Power Source – Step-Down Voltage & Frequency Converters 1800W

- UNI-T Digital Multimeter Tester UT139C

- 50-Amp Extension Cord for RV “100ft”

- Voltage Stabilizer 110/220v

- Hair Dryer “best selling“

- TOSHIBA EM131A5C-BS Countertop Microwave Ovens

Disclaimer: This contains affiliate links to Amazon products. I may earn a commission for purchases made through these links.