I encounter overhead power lines frequently during my travels, and as an electrical engineer, my attention is naturally drawn to them.

Additionally, recognizing the numerous inquiries beginners often have about overhead power lines, I aim to address six common questions in this article. Let’s begin.

Table of Contents

Are Overhead Power Lines AC Or DC?

Overhead power lines generally carry alternating current (AC) rather than direct current (DC). AC is the standard for most power transmission because it can be easily transformed to higher or lower voltages using transformers. This makes it ideal for efficiently transmitting electricity over long distances and distributing it to homes and businesses.

While AC is the norm, there are cases where direct current (DC) is used, particularly in high-voltage direct current (HVDC) systems. HVDC lines are chosen for very long-distance transmission or specialized applications because they reduce energy losses over extremely large distances.

In summary, most overhead power lines use AC, especially in urban and suburban areas. DC is primarily used for specific scenarios like HVDC systems.

Why are Overhead Power Lines Not Insulated?

Overhead power lines are typically not insulated like the electrical wires in your home. This is due to several factors:

- Cost: Using traditional insulation materials, like rubber or plastic, for the vast lengths of overhead power lines would be prohibitively expensive. The sheer scale of long-distance power lines makes full insulation financially unfeasible.

- Practicality: Covering long spans of power lines with insulation would add significant weight, requiring stronger support structures and making installation and maintenance far more challenging.

- Efficiency: High-voltage power lines are designed to minimize energy loss during transmission. Insulating them would increase capacitance with the surrounding environment, leading to energy losses as heat.

Instead of full insulation, overhead power lines are engineered to maintain safe distances between conductors and other objects to prevent electrical arcing. The surrounding air acts as a natural insulator, helping to contain the electrical current within the lines.

Some lower-voltage lines or lines in specific environments may have partial insulation or additional protective measures. However, for high-voltage transmission lines, full insulation is neither practical nor cost-effective.

What Are Voltage Levels of Overhead Power Lines?

The voltage levels of overhead power lines vary depending on their purpose, location, and the distance over which electricity needs to be transmitted. These voltage levels are typically grouped into categories:

1. Low-Voltage (LV) Lines

- Voltage Range: Up to 1,000 volts (1 kV)

- Usage: Primarily used for distributing electricity directly to homes, small businesses, and streetlights.

- Examples: Residential power distribution (e.g., 120/240 V in the US).

2. Medium-Voltage (MV) Lines

- Voltage Range: 1 kV to 69 kV

- Usage: Distribute electricity from substations to neighborhoods or industrial areas.

- Examples: Power to local industrial plants or commercial complexes.

3. High-Voltage (HV) LinesVoltage Range: 69 kV to 230 kV

- Usage: Transmit electricity over moderate distances, typically between cities or to larger substations.

- Examples: Regional power transmission lines.

4. Extra-High Voltage (EHV) Lines

- Voltage Range: 230 kV to 765 kV

- Usage: Transmit electricity over long distances between power plants and major substations.

- Examples: National grid lines for intercity or interstate transmission.

5. Ultra-High Voltage (UHV) Lines

- Voltage Range: Above 765 kV

- Usage: Used for extremely long-distance transmission or in very large power networks to reduce energy losses.

- Examples: Special projects like 1,100 kV UHV lines in countries with large grids (e.g., China, India).

Why These Voltage Levels Vary

- Purpose: Higher voltage levels are used to reduce energy losses during long-distance transmission. Lower voltages are safer and more practical for local distribution.

- Infrastructure: Transmission towers and lines are designed to handle specific voltage levels to balance efficiency, cost, and safety.

These categories help optimize the entire power system, ensuring electricity can travel safely and efficiently from power plants to end users.

The specific voltage levels can vary between countries and regions, and advancements in technology may lead to changes in typical voltage levels over time. The mentioned voltage levels provide a general overview of the classifications for overhead power lines.

Read my article: Why Electricity is Transmitted at High Voltage

What Are OHTL Conductors Made Of?

Overhead High-Tension Lines (OHTL) conductors are typically made of aluminum or aluminum alloy, though steel is sometimes used. The choice of material depends on various factors including the specific application, voltage level, and engineering considerations. Here are the common materials used:

- Aluminum: Aluminum is a popular choice for OHTL conductors due to its lightweight nature and good conductivity. Aluminum conductors are often used in transmission lines where low weight is essential to reduce the load on support structures such as towers. The lightweight property of aluminum makes it easier and more cost-effective to install and maintain.

- Aluminum Alloy: Some conductors are made from aluminum alloys, which offer improved mechanical strength compared to pure aluminum. Aluminum alloys provide a good balance between weight, conductivity, and mechanical properties.

- Steel-Reinforced Aluminum (ACSR): ACSR (Aluminum Conductor Steel Reinforced) is a type of conductor that combines aluminum and steel. The core of the conductor is made of steel, which provides strength, while the outer layer is made of aluminum to enhance conductivity. ACSR conductors are commonly used in medium and high-voltage transmission lines.

Selection Factors

The choice of conductor material depends on factors such as:

- Voltage level

- Span length

- Environmental conditions (e.g., corrosion risk)

- Economic considerations

Aluminum and its composites dominate modern OHTL construction due to their balance of cost, weight, and performance.

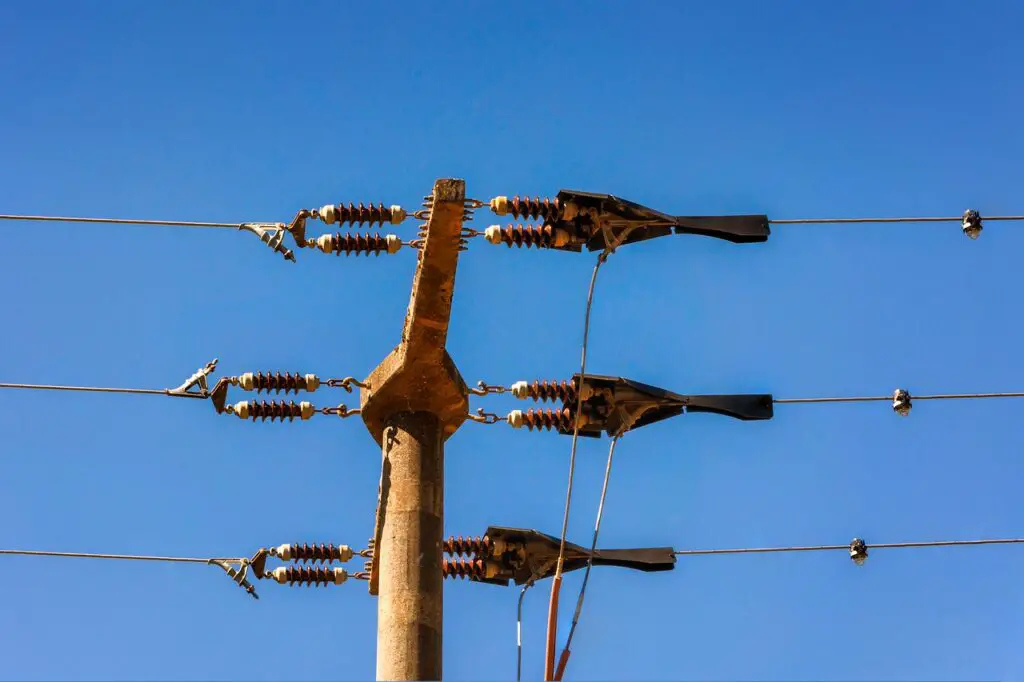

What Are Power Line Insulators Made Of?

Power line insulators are essential components of overhead power line systems. They serve two key purposes:

- Support the conductors (wires that carry electricity).

- Insulate the conductors from the structures holding them, preventing electricity from flowing into the supporting towers or poles.

Materials Used for Insulators

Insulators are made from materials with high electrical resistance and strong mechanical properties. The most common materials are:

- Porcelain

- A traditional material for power line insulators.

- Advantages:

- High mechanical strength.

- Excellent electrical insulation.

- Durable and resistant to environmental factors like UV radiation and pollution.

- Common Use: Suitable for high-voltage applications and demanding environments.

- Glass

- Similar to porcelain in its insulating properties.

- Advantages:

- Strong electrical insulation.

- Resistant to weather and environmental changes.

- Often used in less demanding applications compared to porcelain.

- Polymer (Composite) Insulators

- Modern insulators made from materials like fiberglass-reinforced epoxy or silicone rubber.

- Advantages:

- Lightweight, making them easier to transport and install.

- Excellent resistance to pollution and environmental factors.

- Less prone to breaking compared to porcelain or glass.

- Common Use: Increasingly popular in modern power lines, especially in polluted or coastal areas.

Choosing the Right Insulator

The type of insulator used depends on several factors:

- Voltage level: Higher voltages require stronger insulators.

- Environmental conditions: Areas with heavy pollution or extreme weather may require more durable materials.

- Application needs: Transmission versus distribution systems often have different requirements.

In summary, power line insulators play a vital role in ensuring the safety and efficiency of electrical systems. The choice of material—porcelain, glass, or polymer—depends on the specific demands of the power line system.

Why Does Rain Not Cause Overhead Power Lines Short Circuit?

Rain alone typically does not cause short circuits on overhead power lines. These systems are specifically designed to handle various weather conditions, including rain, without compromising their functionality. Here’s why:

1. Insulation

- Overhead power line conductors are often coated with insulating materials like polymers, which prevent electricity from escaping to the environment, even when wet.

- In high-voltage lines where conductors are not fully insulated, the surrounding air and design of the system still provide effective insulation.

2. Safe Spacing

- The conductors are spaced far enough apart to prevent electrical arcing, even in rainy or humid conditions.

- Proper spacing ensures that water droplets, which could temporarily bridge a gap, do not lead to short circuits.

3. Weather-Resistant Design

Overhead power lines are engineered to withstand rain, wind, and temperature changes.

- Materials used in their construction are durable and resistant to degradation caused by exposure to the elements.

Potential Issues in Severe Weather

While rain alone is rarely a problem, more extreme weather conditions can lead to power line issues:

- Storms or high winds can cause trees or debris to come into contact with power lines, potentially creating short circuits.

- Ice accumulation can increase the weight on power lines, leading to sagging or breakage.

- Corona discharge, a phenomenon where electricity ionizes the air around high-voltage conductors, can occur more easily in wet conditions but is mitigated by devices like corona rings.

Preventive Measures

- Engineers design systems with grounding and other protective features to handle lightning strikes and electrical surges.

- Regular inspections and maintenance ensure the system remains safe and reliable under various environmental conditions.

In summary, rain itself is not a significant threat to overhead power lines due to their robust design and protective measures. However, extreme weather conditions can pose risks that require additional considerations and proactive maintenance.

For more details about short circuits read my article here.

Why Do OHTL Insulators Have Skirting?

Overhead High-Tension Line (OHTL) insulators often have skirts or sheds as part of their design. These skirts serve a specific purpose related to the performance and reliability of the insulator in various weather conditions. Here are the main reasons why OHTL insulators have skirts:

- Pollution and Contamination Resistance: Skirts are designed to provide an additional layer of protection against pollution and contamination. In areas where the atmosphere contains pollutants, such as industrial areas or coastal regions, contaminants can be deposited on the insulator surface. The skirts help to shed or repel these contaminants, preventing the formation of a conductive layer that could compromise the insulator’s performance.

- Flashover Prevention: Flashover is a phenomenon where electricity arcs across the surface of an insulator, usually due to contamination or the presence of conductive deposits. Skirts play a crucial role in preventing flashovers by reducing the likelihood of contaminants accumulating on the surface of the insulator. The shedding action helps to break the continuity of the conductive path and maintain the insulator’s electrical integrity.

- Rain and Water Shedding: Skirts are also effective in shedding rainwater. By preventing the accumulation of water on the insulator surface, skirts reduce the risk of leakage currents and flashovers. Efficient water shedding is particularly important during rainy conditions to maintain the insulator’s insulating properties.

- Corona Control: Skirts can contribute to corona control. Corona discharge, which can occur in high-voltage systems, is associated with energy losses and audible noise. Skirts help manage the electric field around the insulator, minimizing the risk of corona discharge and associated issues.

In summary, the skirts on OHTL insulators are designed to enhance the insulator’s performance in challenging environmental conditions.

what are the orange balls on power lines?

The orange balls on power lines are called aerial marker balls or power line markers. They serve several purposes, primarily related to safety and visibility:

1. Visibility for Aircraft

- The primary purpose of these marker balls is to make power lines more visible to low-flying aircraft, such as helicopters, planes, or drones. This is especially important near:

- Airports

- Hilly or mountainous areas

- River crossings where planes might fly low

- Helipads or emergency landing zones

The bright orange color (and sometimes red, white, or yellow) ensures that the lines are easily visible even from a distance.

2. Identification for Maintenance Crews

- These markers can help maintenance crews identify the location of power lines more easily when inspecting or repairing them.

3. Weather Resistance and Safety

- The balls are designed to withstand harsh weather conditions and reduce the risk of power line accidents caused by poor visibility.

Placement Guidelines

- The markers are usually spaced 200 feet (about 60 meters) apart on the line, but this may vary depending on local regulations or the specific location.

- They are often installed on the shield wire (the topmost wire) to minimize wind drag and maintain the stability of the power lines.

These balls are a small but crucial component in ensuring the safety of both the power grid and the people or vehicles that might come into contact with it.

Don’t Leave Empty-Handed!

Install my Free Android App on Google Play:

Electrical Cables Most Common Tables “Cables Tables”

And, my Electrical Calculations App “Fast Electrical Calculator”

Discover more great content by subscribing to My channel

Looking to stay ahead of the game in the world of electrical engineering? Subscribe to my YouTube channel and gain access to exclusive content you won’t find anywhere else!

The staff I recommend

(Amazon Affiliate Links to products I believe are high quality):

- Economy 120 Volt/60Hz AC Power Source – Step-Down Voltage & Frequency Converters 1800W

- UNI-T Digital Multimeter Tester UT139C

- 50-Amp Extension Cord for RV “100ft”

- Voltage Stabilizer 110/220v

- Hair Dryer “best selling“

- TOSHIBA EM131A5C-BS Countertop Microwave Ovens

Disclaimer: This contains affiliate links to Amazon products. I may earn a commission for purchases made through these links.