Table of Contents

what is a synchronous generator?

A synchronous generator (also known as an alternator) is a type of electrical machine that converts mechanical energy into electrical energy in the form of alternating current (AC). It operates at a constant speed, maintaining synchronization with the frequency of the power system to which it is connected.

Key Components:

-

Rotor:

- The rotating part of the machine.

- Typically contains a field winding that is energized by direct current (DC) to produce a magnetic field.

- Can be either a salient-pole or cylindrical type, depending on the application.

-

Stator:

- The stationary part of the machine.

- Contains the armature winding where the AC voltage is generated.

-

Excitation System:

- Provides DC current to the rotor winding to create a magnetic field.

- Can be powered by an external source or through self-excitation mechanisms.

How It Works:

-

Mechanical Input:

- A prime mover (e.g., a steam turbine, gas turbine, or diesel engine) drives the rotor, converting mechanical energy to rotational energy.

-

Electromagnetic Induction:

- As the rotor spins, its magnetic field cuts across the stator windings.

- This induces an alternating voltage in the stator windings according to Faraday’s Law of Electromagnetic Induction.

-

Synchronization:

- The rotor speed is synchronized with the frequency of the electrical grid (e.g., 50 Hz or 60 Hz).

- The generated AC voltage has a frequency that matches the grid frequency.

Applications:

- Power Plants: Synchronous generators are widely used in large power plants to generate electricity.

- Industrial Facilities: They provide reliable power for heavy industrial operations.

- Renewable Energy: Used in wind turbines and hydroelectric plants.

Advantages:

- High efficiency.

- Capable of producing high power outputs.

- Can operate in parallel with other generators to maintain a stable power supply.

Limitations:

- Requires a precise control system to maintain synchronization.

- Higher maintenance compared to some other types of generators (e.g., asynchronous or induction generators).

- Read Also My Other Article: What Is AC Generator? All about It!

- Generator synchronization.

Synchronous Generator Construction

An alternator, also known as a synchronous generator, has two main components: the stator and the rotor. Each plays a crucial role in the generation of electrical power.

Stator

The stator is the stationary part of the alternator. It houses the armature windings, where the electrical voltage is generated. These windings are connected to the external circuit, meaning the output power is delivered directly from the stator.

To minimize energy losses such as hysteresis and eddy currents, the stator core is constructed from laminated steel with a high silicon content. This design improves efficiency and reduces heat generation.

Rotor

The rotor is the rotating component responsible for creating the magnetic field, or field flux. It contains windings that are energized by a direct current (DC) source. When DC flows through these windings, it produces a magnetic field.

The rotor is driven by a mechanical prime mover (such as a steam turbine, gas turbine, or diesel engine). As the rotor spins, its magnetic field cuts through the stator windings, inducing an alternating voltage according to Faraday’s Law of Electromagnetic Induction.

In summary, the stator generates and supplies the electrical output, while the rotor produces the magnetic field necessary for voltage generation. Together, they form the core of an efficient and reliable electrical power generation system.

What are Carbon Brushes?

The older designs of the synchronous generator had an issue of feeding the rotor with its DC current while it’s rotating, to produce field

Using carbon brushes to feed the rotor with DC current was the solution.

Brushes need continuous maintenance! so, the modification was to use a separate generator on the rotor shaft.

Nowadays, brushless excitation is the solution of brushes many issues. What is brushless exciter?

Brushless Exciter

A Brushless Excitation System is a method of supplying field current to the rotor of a synchronous generator without the use of slip rings or carbon brushes. This design eliminates the need for direct electrical contact, reducing maintenance and improving reliability.

Unlike a Static Excitation System, which relies on an external DC power source to provide field excitation, a brushless system operates independently. It doesn’t require an external power supply at start-up. Instead, it uses residual magnetism—the small amount of magnetic field that remains in the rotor after the generator is turned off—to initiate the excitation process.

This residual magnetism helps build up the magnetic field required to generate electricity. Over time, as the rotor spins, the magnetic field strengthens and sustains itself, enabling efficient operation without external assistance.

Curious about residual magnetism? Let’s explore what it is and why it’s so important.

What is Synchronous Generator Residual Magnetism?

Synchronous generator residual magnetism refers to the small amount of magnetic flux or magnetic field strength that remains in the rotor’s magnetic circuit when the generator is not actively generating electricity.

How It Works:

-

Initial Excitation:

When a synchronous generator starts without an external excitation source, it relies on residual magnetism to create the initial magnetic field in the rotor. -

Creation of Residual Magnetism:

During previous operation, the rotor’s field winding was energized with direct current (DC), magnetizing the rotor and leaving a residual magnetic field after shutdown. -

Starting the Generator:

Upon startup, this residual magnetic field generates a small voltage in the stator. This initial voltage helps the generator produce electricity and synchronize with the grid frequency. -

Self-Excitation:

Once electricity generation begins, the internal voltage supplies DC current to the rotor via an exciter or Automatic Voltage Regulator (AVR). This strengthens the magnetic field, enhancing the generator’s performance.

Key Considerations:

- Residual magnetism is vital for self-excitation in smaller generators, offering a simple and cost-effective start-up solution.

- Larger generators often require separate excitation systems for precise control of the magnetic field, as residual magnetism alone may not provide sufficient excitation.

What is Generator Excitation Field Flashing?

Field flashing is the process of restoring the residual magnetism in a generator’s exciter field. This procedure becomes necessary when the generator fails to build up voltage, typically due to insufficient residual magnetism in the exciter or main generator fields.

Why Is Field Flashing Needed?

- Loss of Residual Magnetism: Over time, or after long periods of inactivity, a generator may lose its residual magnetism, making it unable to self-excite and generate voltage.

- Insufficient Voltage Build-Up: Without enough residual magnetism, the initial magnetic field required for excitation is too weak, preventing proper voltage generation.

How Field Flashing Works

Field flashing involves applying a temporary direct current (DC) to the exciter field windings. This DC current re-establishes the necessary magnetic field, allowing the generator to produce voltage. The current can come from:

- A battery.

- A housing unit that supplies DC.

- Rectified AC, where alternating current is converted to direct current.

This process usually takes only a few seconds and is common even for small, portable generator sets during routine operation.

Steps for Field Flashing

-

Disconnect Exciter Leads:

- Disconnect the exciter field leads labeled F+ and F- from the voltage regulator.

-

Connect to Battery:

- Connect F+ to the positive terminal of the battery.

- Briefly touch F- to the negative terminal of the battery for about 5 seconds.

-

Reconnect Leads:

- Reconnect the exciter leads (F+ and F-) to the voltage regulator.

-

Start the Generator:

- Start the generator and observe if it builds up voltage.

-

Repeat If Necessary:

- If the generator still doesn’t build voltage, repeat the flashing process.

Additional Notes:

- If field flashing alone doesn’t restore sufficient voltage, external current injection into the rotor from another source may be required.

- Field flashing is a quick and effective way to restore the generator’s ability to self-excite and operate efficiently.

By following these steps, generators of all sizes can regain their capacity to build voltage, ensuring reliable operation.

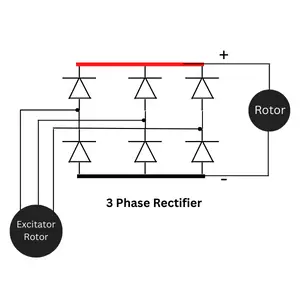

What Is The Function Of The Diode Bridge In A Generator Exciter?

The diode bridge job is to rectify ِcurrent from the exciter rotor, i.e. convert it from AC to DC.

This direct current is sent straight to the primary rotor field coils, which require DC current to excite the main rotor. The automated voltage regulator adjusts the field current to keep the AC output voltage constant as the load varies.

Because the magnetic field requires DC electricity, this procedure is needed for a generator’s alternator to function.

Before the exciter’s AC output can be utilized to create electrical energy, it must be converted to DC power. This occurs within a diode rectifier.

Why Does a Synchronous Generator Need a Battery?

While a synchronous generator itself doesn’t inherently require a battery for its primary operation, there are specific scenarios where batteries play a crucial role in systems associated with the generator. Here’s a breakdown of their key uses:

Engine Starting

In setups where the synchronous generator is driven by an internal combustion engine (e.g., diesel or gas engine), a battery is essential to start the engine. The battery powers the starter motor, which cranks the engine until it reaches self-sustaining speed. Once the engine is running, it drives the generator to produce electricity.

Backup Power

Batteries are often used in uninterruptible power supply (UPS) systems alongside synchronous generators. They provide instant power during the brief transition when the generator is starting up. This ensures continuous power during grid outages or when switching from the main supply to generator power.

Control and Monitoring Systems

Modern synchronous generators are equipped with control, monitoring, and protection systems. These systems often rely on batteries for:

- Powering control circuits.

- Operating sensors and protection relays.

- Ensuring communication with monitoring devices.

In case of a power failure, the battery ensures that these systems remain operational to safely control or shut down the generator.

Excitation System

Some synchronous generators use a battery as part of the excitation system, particularly during startup. This is common in systems where the generator’s exciter (a smaller auxiliary generator) or an Automatic Voltage Regulator (AVR) needs an initial power source to energize the rotor’s field winding. Once the generator begins producing power, it can sustain its own excitation.

Read also my detailed article : Electrical generator batteries, 6 important Answers.

Don’t Leave Empty-Handed!

Install my Free Android App on Google Play:

Electrical Cables Most Common Tables “Cables Tables”

And, my Electrical Calculations App “Fast Electrical Calculator”

Discover more great content by subscribing to My channel

Looking to stay ahead of the game in the world of electrical engineering? Subscribe to my YouTube channel and gain access to exclusive content you won’t find anywhere else!

The staff I recommend

(Amazon Affiliate Links to products I believe are high quality):

- Economy 120 Volt/60Hz AC Power Source – Step-Down Voltage & Frequency Converters 1800W

- UNI-T Digital Multimeter Tester UT139C

- 50-Amp Extension Cord for RV “100ft”

- Voltage Stabilizer 110/220v

- Hair Dryer “best selling“

- TOSHIBA EM131A5C-BS Countertop Microwave Ovens

Disclaimer: This contains affiliate links to Amazon products. I may earn a commission for purchases made through these links.